We are one of leading producers of sugar in Peshawar, KPK Pakistan

Group Overview

The Thal Industries and Almoiz Industries ranks amongst the most prominent commercial and industrial business houses in Pakistan.

Financial Highlights

Financial Highlights Its shares are quoted on the Karachi, Lahore and Islamabad Stock Exchanges.

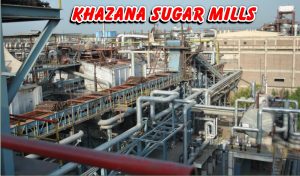

Manufacturing Facilities

This plant has a cane crushing capacity of 5500 TCD and an installed generation capacity of 8.5 MW.

Introduction

Khazana Sugar and Distillery Mills is located in Peshawar, the capital of KPK, Pakistan. We have extensive sugar producing units which produce White Refined Sugar, Brown Suger, Sugarcane Molasses, Ethanol, Industrial Rectified Alcohol and other allied products. We are also a member of Peshawar Chamber of Commerce and Industry, and Pakistan Sugar Mills Association.

Khazana Sugar Mills (Private) Limited (the Company) was incorporated on October 22, 1998 as a Private Limited Company .Initially, Khazana Sugar Mills was a fully owned project of sarhad development authority (SDA). In 1998, ch Ashiq Khalid owned this mill with all its asserts including Land, Machinery, Building etc, in a Government auction and develop/run this mill successfully. After the death of Ashiq Khalid in 2021, his elder son Fukhera Khalid is the current chairman of the mill.

Sugar

Sugar is one of the most popular sweeteners used in Pakistan today. From baked goods to beverages, this all-purpose sweetener has been a favorite for centuries. White sugar is the crystallized sucrose extracted from either sugarcane or sugar beets. After harvesting the sugarcane or sugar beets, the juice is extracted and boiled down to remove moisture. As the moisture diminishes, the natural sucrose in the juice begins to crystallize. The crystallized sugar is removed, leaving other extracts behind in the form of molasses, using rapidly spinning centrifuges.

Molasses

The second most contributing factor derived from crushing sugar cane is the extraction of molasses that are used in production of sweetened products i.e. in chocolates, preparation of medicines and a major ingredient of ethanol production used in fuel and others. The most common forms of molasses are made from either sugar black strap molasses cane or sugar beet juice which is boiled down to a syrup. Sugar crystals are extracted from the syrup, and the remaining dark liquid is molasses.

Bagasse

Bagasse is a fibrous residue left over after the sugarcane is crushed. The fiber content of bagasse (cellulose) is used in cellulose industries like the pulp, paper, particle boards, cattle-feed etc. This is valued as an important by-product and efforts are under way to save as much as possible to produce the value-added products. Bagasse is traditionally used as captive fuel in sugar factory boiler for raising steam required for the generation of power and driving the prime movers. In recent years, the technology for making different products such as papers, boards and chemicals are developed and many mills have introduced energy conservation measures to save as much as possible, even after using it as captive fuel.

Mud

Sugarcane press mud is the residue of the filtration of sugarcane juice. The clarification process separates the juice into a clear juice that rises to the top and goes for manufacture, and a mud that collects at the bottom. The mud is then filtered to separate the suspended matter, which includes insoluble salts and fine bagasse. This industrial by-product is mostly used as soil conditioner and soil fertilizer for agricultural lands.

Our Business In UK

USEFUL INFORMATION ON SUGAR

- Global Production

- Sugar Crushing

- Consumption of Sugar

- Sugar Export

Pakistan Sugarcane crushing season 2018-2019 appears to be challenging. Pakistan’s production is forecast to be down by 15-25 percent due to reduced area as farmers shifted to other crops such as cotton and corn because of better prices and faster return on their investment.

Consumption continues to grow modestly with a developing food processing sector and growing population. Exports and stocks are projected to decline due to the lower production while final levels will depend on government policies

Exports and stocks are projected to decline due to the lower production while final levels will depend on government policies. In December 2018, the Government of Pakistan allowed 1.1-million-ton sugar export. Millers remain unhappy still as the latest export quota is not accompanied by subsidy and Pakistani sugar output remains uncompetitive in global market due to low sucrose recovery rate.

Company Gallery

CEO MESSAGE

Khazana Sugar Mill processes and makes finest sugar by state of the art plant and deliver it all over Pakistan. Khazana Sugar Mill is a vital part of the rural communities, providing thousands of jobs in multiple capacities.